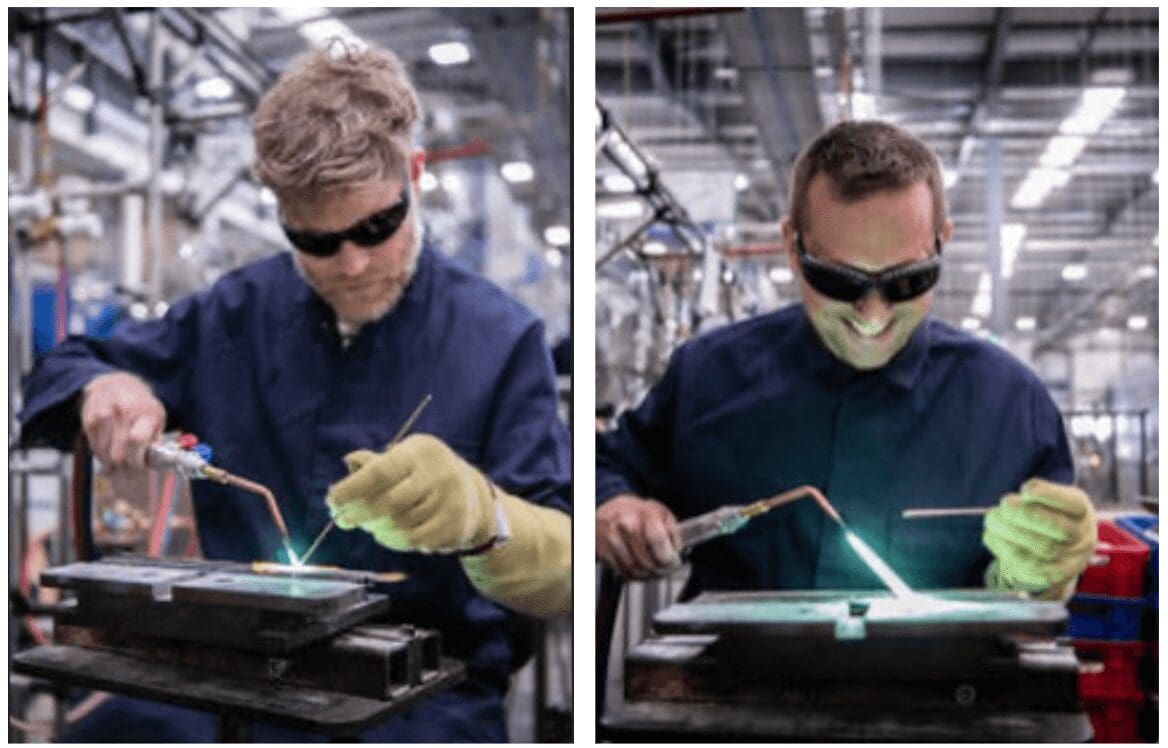

For many years now, Brompton bikes have come in a vibrant array of colours. From standard to premium finishes, mix and match extremities, and a myriad of special edition bikes released each year, you may wonder how they get that consistent great finish. We visited the factory in Greenford to find out how they do it. (That’s us below taking brazing lessons from Abdul El Saidi, Brompton’s head brazer).

Wales of a Time (A Lot of Time!)

Brompton began full-time production of their one-of-a-kind bikes under some railway arches in Bollo Lane, Brentford, in 1988. As demand grew, the team moved into a larger, 22,000 square-foot factory in nearby Lionel Road South, near Kew Bridge station.

In these early phases, there simply wasn’t space to do in-house painting, so the bike frames were loaded onto a truck and driven to a specialised paint facility over 325 km away in Wales. Not terribly environmentally friendly!

Painting in House

In 2016, Brompton outgrew their old digs, moving its factory from Brentford to an 84,000-square-foot facility in Greenford, West London. They transformed a simple warehouse into a state-of-the-art factory. The new facility allowed Brompton to boost production to around 100,000 folding bikes annually, meeting growing global demand while keeping their skilled workforce of over 300 employees.

The relocation and expansion also meant that they could bring the painting in-house, saving time, fuel, and money. Brompton invested over £1,000,000 on a first-class powder-coating machine. Powder coating offers a thick, durable, and long-lasting finish. Coupled with the pretreatment process, this improves longevity and gives that famous fine Brompton finish.

Here’s how it works:

First, the frame components are pretreated. This process is crucial for preventing corrosion on the steel. Brompton employs an eco-friendly Chemetall Oxsilan process, which ensures high corrosion resistance and paint adhesion while meeting strict environmental standards. The pretreatment plant features high-efficiency gas burners, stainless steel construction, and advanced water treatment.

After pretreatment, components dry in a gas-fired oven at 302 degrees for seven minutes. They then move to a pressurized, ventilated enclosure to prevent contamination. An automatic powder coating booth sprays a plastic powder onto the frame part using an electrostatic charge. Manual touch-ups ensure complete coverage. The components cure in an oven at 392 degrees for 25 minutes before cooling and undergoing rigorous inspection. Only perfect parts make the cut; anything less is recycled.

Cerakote

In 2025 Brompton launched a new Cerakote process. Cerakote is a ceramic-based coating known for its exceptional durability and thinness. Originally developed for the arms industry, it offers far greater resistance to chips, scratches, and corrosion than traditional paint or powder coat. Cerakotes are very thin so it doesn’t affect precision tolerances, meaning folding mechanisms and fittings continue to operate smoothly. This also makes Cerakotes lighter, which is why Brompton launched Cerakotes on their titanium T-Line bikes exclusively.

But, Brompton isn’t from Toronto, where our city pours salt in the winter, and the roads spray up debris like a sandblaster. We think it’s cool that Cerakotes are super lightweight, but we love Cerakote for the durability. That’s why we teamed up with Red Hill Armoury, who can Cerakote any Brompton for a very reasonable price. Best of all, when you get your Brompton Cerakoted, you get a complete overhaul in the meantime, including new frame bushings throughout. You can learn more here!

- Want to see the painting process in action? Check out Brompton’s video of the Nine Streets Edition.

- See all Past Colour Guides and Associated RAL Codes